The use of forensic casting materials starts as soon as a 3D impression is needed to be documented. And for analyzing a 3D impression, a forensic investigator requires a cast for compression with a reference sample. But how to choose which casting material is best on different surfaces. Here is a short table:

| Surfaces With Impressions | Casting Materials |

|---|---|

| Normal soil | Dental stone, Silicones, Polyurethane (PU) |

| Dentistry Work | Siloxanes, PVS, Dental Stones, Alginates |

| Sand | Dental stone, Silicones, Polyurethane |

| Snow (Know More) | Sulfur cement, Snow stone, dental stone |

| Low temperature | Sulfur cement, Isomark, dental stone |

| Wet Condition | Dental stones, Silicones, PVS, PUs, Epoxies |

| Underwater | Dental stone, Silicones, PVS, PUs, NuCast |

| Tool marks | Woods metal, Mikrosil, dental stone |

| Tire marks on soil | Dental stone, NuCast 180XL, |

| Tire marks on snow | Sulfur Cement, Snow stone, Dental stone, |

| Quickly on surface | NuCast 180, 180XL (less than 5 minutes) |

Characteristics of Ideal Casting Material in Forensic

Following are the properties that make any casting material more desirable for forensic use:

- Cost-effectiveness. Estimation of cost should be calculated based on how much cast is required on a daily basis. But as the rightful duty of forensic scientists, you should always prefer what is good for the case and tackling evidence. However, for practice purposes costliness can be compromised.

- Ease of use. It should be easy. Just pour the right amount of cast powder in a liquid, or readymade pastes with a minimal amount of additional products (catalysts and fibrous reinforcing structures).

- Ease to wound out without damaging the original tool marks. This ensures multiple casting of an impression with different casting materials without the loss of any details.

- Good setting characteristics. The early period of hardening (stiffening) is called the settling of casting materials. In this period, it can be distributed and remixed without hardening for a short period of time.

- Good curing characteristics. Curing is the process that controls the loss of moisture from casting material after it has been placed in position. This ensures full effective strength without forming cracks.

- Hardening Time. Hardening depends mostly on the surrounding environment. More the hardening time, make it undesirable to crime scene groundwork. Mostly for the outdoor work fields, polymer-based casting is preferred as it sets in a minimal time.

- Dimension stability. The dimension should be stable so that each mold production is of an accurate impression of original.

- Surface stability. Resist cracks and surface stability over a long period of time.

- Elastic memory. When the cast is wound-off the sample, it undergoes partially reversible distortion to its original casted shape (like spring or rubber). And this defines elastic memory.

- Temperature and Hardening. Not all cast work at high temperature, or in case, low temperature (less than 0ºC). Some resist hardening while some don’t catalyze well, or some harden very quickly.

- Viscosity. As per finding, more viscous a casting material is harder is the casted remains and higher the detailing reproduction ability.

- Micron Details. Ability to capture and replicate finer detailings on the scale of microns

- Different Substrates. Versatile use on different substrates.

- Opaque Surface Definition: Under the microscope, the cast appears to be opaque.

- Longevity. For a long time, at least until the case is closed, the casting material resists deterioration from storage.

P.S. For documenting any kind of 2D impressions like a dirty footprint on a flat surface, it can be lifted using a Gelatin lifter or Electrostatic Dust lifter.

Types of Forensic Casting Materials With Uses

Following are the types of casting materials that are commonly used for forensic purposes.

1. Plaster of Paris

The most common casting material that is surely cheap for bucks is Plaster of Paris (also called beta calcium hemihydrate).

Preparation: It is a form of the fine white powder of calcium sulfate hemihydrate (CaSO4⋅ 1/2H2O) prepared by heating calcium sulfate dihydrate (or gypsum) to 120 °C–180 °C until 3/2 of water is boiled off.

CaSO4.2H2O + Heat → CaSO4.2H2O + 3/2H2O

In the casting process, when water is added to the dry POP, the water molecules incorporate themselves into the crystalline lattice of the calcium sulfate dihydrate releasing heat as kinetic energy (opposite of the above reaction).

Working Paste Preparation: 2 parts of plaster of Paris and 1 part of water and mix well. And to reduce the settling time, a small amount of potassium sulfate can be added.

P.S. Majorly there are three types of plasters based casting material including Paris, dental and ceramic. All three of them are obtained from Gypsum (CaSO4⋅ 2H2O) which is a hydrated form of calcium sulfate. They are prepared by mixing the fine powder with a hardening agent (usually water).

Advantages:

- Cheap and easily available.

- Quick setting.

- Ability to resist shrink or crack when dry.

- Mainly employed for osteology and paleontology.

Disadvantages:

- The quality and fineness of POP define how good they are at casting the minute characteristic of the tools’ mark impression.

- Capturing details is not good, making it hard to use as a tool to mark casting film.

- Soft and easily scratched.

- Skill required for precise application and safe removal of casts made from it

- Sensitivity of hardened plaster of Paris to water exposure

Note: Moulage is a French term that refers to any moulding or casting substances. The term was popular in 19th-century books but is now rarely used for casting material. In today’s world, the term “moulage” refers to materials used to simulate and create wounds on a person for medical training or theatrical purposes.

2. Dental Stone

More durable, small particle size, higher strength, and low porosity (requires fairly less water) than Plaster of Paris. It is also called alpha-calcium hemihydrate. Commercially, the dental stone is available in various colors and mixing forms. It is majorly used in dental line preparation.

Preparation: Gypsum is heated (120–150°C) under high pressure (using an autoclave steam pressure instrument) and then fine ground produces dental stone.

- It comes in different consistency ratings or has a water/powder ratio that is given on their containers.

- A consistency rating of 35, states 35c.c (ml) of water to 100 g of casting material.

- For tire and shoe tracks, a 30 to 35 water/powder ratio is recommended.

- Potassium sulfate can be added as a catalyst to accelerate the setting.

Working Dental Stone Paste:

- First, put 35ml of water, and slowly pour the 100 g of powder in it.

- You will see the powder get down to the bottom leaving an oasis of water.

- Allow it to be drawn, then thoroughly mix until it forms a consistent paste-like pancake batter.

Advantages:

- The best and most affordable alternative of plaster of Paris.

- Has higher compressive strength.

- Detail on casts can be excellent.

- Shrinkage is minimal with more surface durability.

- Relatively stable and higher longevity once set.

Disadvantages:

- Hard, but brittle, and can shatter if dropped.

3. Siloxanes (Silicones)

Silicones are elastomers that have the ability to stretch, harden quickly and regain their original shape when acting force is released. These polymeric compounds are made from a chain of siloxanes (RSi-O-SiR-O), where R commonly represents the methyl (CH) group.

Commercially available casting materials are Sta-Seal®, Microsil®, Coltoflax®, Xantopren®, and Coltex®

Structure: A polymeric chain started with a polymethyl silicone with a methyl group and a conjugated ester catalyst of silicic acid and organometallic salt.

Note: Silicones and silicon are not the same compounds. Silicon is a crystalline element that is used to make semiconductors and microchips. Silicone, on the other hand, is a chemical compound that is synthetic inert.

Preparation Silicones Casting Material: Commercially available as a two-part system.

- Base: silicone-polymer base

- Catalyst (hardener): ester catalyst with doped color

- Mix a small (about 5% to 10%) catalyst to base and mix well for 15 to 20 minutes without introducing bubbles.

- Pour the paste from the side, and let the silicone fluid on marks. This ensures bubble-free casting.

- It is set by the condensation polymerization because of the silicone polymer and catalytic reaction.

Advantages:

- Greater tear strength

- Quick curing and setting time

- Reproduce with greater detailing

- Less smelly

Disadvantages:

- Silicones are quite shrinkable.

- Very quicker setting in colder conditions.

4. Polyvinyl Siloxane (PVS)

A polymeric chain starting with a polymethyl siloxane with a vinyl (C2H3) group, containing at least 500 unit molecules, with platinum salt as an acting catalyst. In other words, they have silicone prepolymers with vinyl groups that polymerize via addition polymerization.

They are more favorable and widely accepted as casting material in forensic science. This is because PVS shrinking ability is only ¼ to 1/10 than siloxanes.

Commercially available products for forensic use are Permadyne®, Reprosil®, Aquasil, and Impregnum®.

Preparation PVS Casting Material: They are usually available as a three-part system:

- Base 1: silicone-polymer base of vinyl polymethyl siloxane, usually white.

- Base 2: a siloxane prepolymer with hydrogen groups.

- Catalyst: elemental catalyst, with doped color.

- Initiator: Chloroplatinic acid for initiating polymerization reaction. Majorly, added with catalyst solution.

- Mix both pastes (base1 and base2) in equal amounts and add catalyst and mix for at least 15 minutes. Note: If there is a separate initiator solution, add a small amount of it and mix the whole batter for the next 15 to 20 minutes.

- Pour the paste from the side, and let the vinyl polysiloxane fluid on impressions.

P.S. Most of the currently available vinyl polysiloxanes, for easiness, come in two-part systems. So, don’t get confused that a two-part system is always for siloxanes.

Advantages:

- Dimensional stability with greater tear strength.

- Quick curing and setting time (roughly 3 minutes at room temperature), make it good for fieldwork.

- Good at detail capturing.

- Easily pulled off from the surface.

- Fewer chemical smells make it best for teeth casting.

- Toolmarks and ballistic casting

Disadvantages:

- Highly hydrophobic.

- Oxygen is sometimes a byproduct.

5. Polyether Gums

They are another form of elastic polymer that was first developed in the late 1960s. These elastomer’s impression materials are fairly advantageous over simple siloxanes and PVS including great detailing, short working time, and hydrophilic nature.

Aside from that, they are fairly hydrophilic, allowing for good wettability and easy casting. The most common commercial polyether gums are from Permagnum®.

Working Polyether Gums Paste: Like PVS, they are commercially available in a two-part system:

- Base Paste: a mix of ethyleneimine group polymer along with fillers, plasticizers, and colloidal silica.

- Catalyst: Aromatic sulfonic acid ester and thickening agents.

- On mixing for 5 to 10 minutes, there is a polymerization reaction that opens ethyleneimine groups.

- Pour the mixture on the side.

Advantages:

- Short working and setting time.

- Single viscosity makes casting paste cover the surface uniformly.

- Provide good dimensional stability.

- Easy to use.

Disadvantages:

- Bad taste.

- Questionable for dental marking of higher rigid than any other elastomers.

- Stiffness can also result in cast breakage on removal.

- Low to moderate tear strength.

- High absorption factor makes it unpleasant to store in high humidity.

- Clinically acceptable casts period is up to 7 days.

- Unfit for suspects allergic to latex.

Also Read: Over a Barrel Case: Forensic File Case of Clifford and Alma Merck

6. Polysulfide Gums

They are inexpensive and give relatively more working time than siloxanes. The base paste contains a liquid polysulfide prepolymer with a polymerized chain of mercaptan (–SH) group along with catalyst pastes. Polysulfide gums are also called mercaptan or “Rubber Base.”

Working Polysulfide Gum: The setting is governed by the classic condensation polymerization reaction (like other elastomers) and it comes in a two-part system.

- Base paste: Contains polysulfide polymer. In addition to this, the base paste also contains:

- Fillers: A small amount of fillers for consistency and adds required strength when set. Common fillers are zinc oxide, zinc sulfate, or titanium dioxide.

- Plasticizers: decrease viscosity and plasticity, and increase workability and performance.

- Sulfur: a small quantity of sulfur (~0.5%) to accelerate the reaction.

- Catalyst: Lead dioxide, hydrated copper oxide, or organic peroxide as a catalyst with some amount of:

- Plasticizer: sulfur and dibutyl phthalate

- Nonessential fillers

- Retarders: to control the rate of setting reaction. Eg: oleic or stearic acid

- The reaction starts as the catalyst is added to the base and propagates the polymerization network and batter should be poured within half an hour because water is a byproduct of this condensation reaction that may diminish the accuracy.

- Elevating temperature and humid condition accelerates the setting time.

Advantages:

- Good tear strength and quite flexible.

- Economical.

- Staining due to mercaptan.

- Higher working time than silicones.

Disadvantages:

- Loss of water from the setting material makes it shrink i.e. less dimensional stable.

- Long setting time

- Unpleasant odor of sulfur

- In cold and dry conditions, the setting time is even stretched.

7. Alginates

These are the hydro colloidal particles that are extracted as anionic polysaccharides from the cell walls of brown algae. They are mainly employed in dentistry work but can be useful for making any time of tool marks impression.

In addition, Alginates have an excessively high detail capture capacity, since they can even recreate fingerprint ridges. But they suffer from dimensional stability. As a result, they are rarely used in casting positive markings such as tire and shoe print.

Note: According to additional research, the positive prints from alginates are too shrinkable when dry. Even an agency reported that the shoe cast shrank from size 10 to size 8. That’s become the reason why they are no longer used to making positive prints, and their casting resists dentistry work including the jawline, teeth marks, and bite marks on food.

Components of Alginates Paste: The main components are:

- Reactant: sodium or potassium alginate, calcium sulfate

- Fillers: diatomaceous earth, potassium sulfate (stone compatibility)

- Retarder: sodium phosphate

- Flavoring agents: because majorly used for dentistry purposes.

Preparing working paste: The alginates powder is mixed with water in a 1: 3 or 1:2 ratio. The final mix is in the rubbery form of irreversible hydrocolloid gel. Going beyond the 1:3 alginate to water ratio significantly increases the hardening and setting time, and significantly decreases the accuracy.

Advantages:

- Too sensitive to detailing. Even records fingerprint ridges.

- Best for creating a negative impression of teeth.

- Good for creating molding of bite marks in food (eg on bread).

- The material sets quickly.

Disadvantages:

- Less favorable for positive marks such as tire and shoe prints.

- Quick setting time that requires pre-planning and quick hands.

- Less dimensional stability as it dries.

8. Polyurethane (PU)

Polyurethane elastomers materials are made by reacting a polyol with diisocyanate that forms a simple chain. This chain is extended, resulting in a long chain that is further cross-linked to form a polyurethane hard cast.

Components of Polyurethane Casting Resin:

- Polyol

- Diisocyanate

- Chain extenders (curatives)

- Catalysts:

- Not normally needed.

- Weak acids (adipic acid for toluene diisocyanate/amine cures).

- Tin and bismuth catalysts for lower-temperature cures.

- Pigments: as a paste.

- Plasticizers: reactive or non-reactive plasticizer

- Fillers:

- Not generally required.

- Ultrafine silica to increase spreadability used by Aerosil®.

- Nanoparticles have been used to enhance tear properties.

Working Paste preparation for Polyurethane Casting

- Base of the prepolymer of polyurethane.

- Add curative to the prepolymer.

- Add a mixing container in a stream (if required) for melting the base.

- Mix well in a zigzag motion and avoid whipping in the air.

Advantages:

- Allows more precise structure of prepolymer cast.

- Control over color and pigments.

- Manageable variable setting and curing time.

- Dimensional stable because of rigid elastomers.

- Good at detail reproduction.

- High tearing strength.

Disadvantages:

- Strong odor

- Shelf life of the cast is very poor, especially when the temperature is higher. At room temperature for about 1 year, and at 60°C only 2 weeks.

- Degrade in sunlight, changes color to yellow

- Degrade when exposed to organic solvents.

9. Epoxies Casting Materials

Epoxy resins are reactive polymers with an epoxide group that can be polymerized by a variety of reactants including polyfunctional amines, anhydrides, acids, phenols, alcohols, and thiols.

Composition: Most common epoxy resin (90% market share) is produced by a condensation reaction between bisphenol A and epichlorohydrin (1:3 ratio) at a temperature of about 100 °C to produce low weight diglycidyl ether of bisphenol-A.

Working Paste for Epoxies Casting: Commercially available as a two-part system.

- Epoxy Base: paste of polyepoxides resin.

- Hardeners: used to form crosslinked branches. Common hardeners are urea, phenolic, diamine, polyamine, acids, and various acid anhydrides.

- The ratio of epoxy resin to hardener: 1:1 or 4:1.

- Mix well for at least 10 minutes.

Advantages:

- Sets quickly and fast curing time.

- Commonly used in dentistry purposes for scanning electron analysis.

- More viscous consistency than polysulfides.

- Relatively short processing times.

- High tearing strength and rigidity.

Disadvantages:

- Fast setting epoxies produce a good amount of heat. Not suitable for snow.

- Higher cost than other elastomers

- Controlled casting conditions and favors low humidity environment.

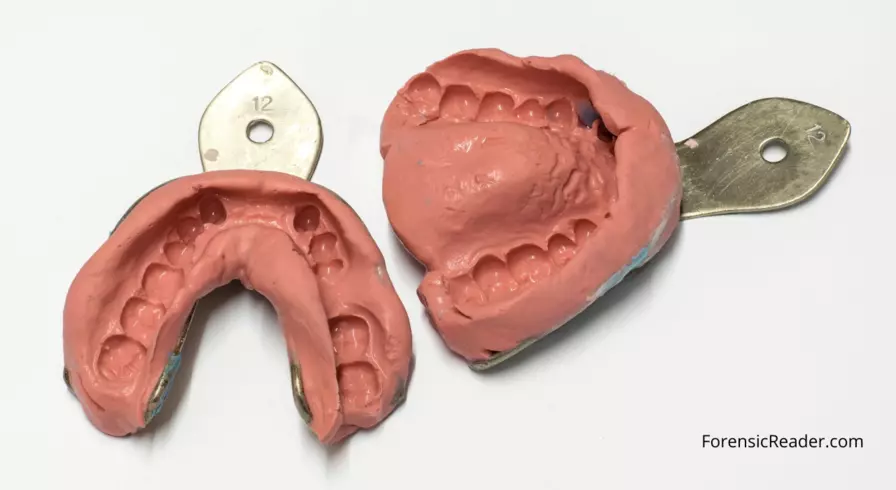

10. Sulfur Cement

Sulfur cement is a modified mixture of sulfur plasticizers and silica. It was first introduced in 2007 as one of the replacements of pure sulfur for shoe impression casting on snow. It is less flammable and setting times are about 20 to 30 minutes. The most commonly available sulfur cement is from Basolit Sulfur Cement.

Working Paste Preparation of Sulfur Cement:

- Sulfur cement is melted using a thick hot plate or any thick heating container.

- As soon as you place the sulfur powder in a hot pot, stir it continuously with a metal rod or wood stick.

- Once melted, the paste should be cooled to a temperature where the crystallization starts. It usually takes 20-30 minutes. For monitoring temperature, you can use an infrared thermometer.

- Make a V-shaped valley at a point away from the shoemaker, and pour the sulfur paste, the viscosity makes it follow over the paint surface.

- The setting and curing time could take around 30 minutes.

Advantages:

- One of the most preferred casting materials for snow.

- Less flammable and stronger.

- High detail capturing ability than pure sulfur and dental stone.

- Even best for capturing tire track details in snow.

Disadvantages:

- Preparation needs assistance and is time-consuming.

- An infrared thermostat is needed for better monitoring.

11. Wood’s Metal (Casting of Toolmarks)

Wood’s metal is a Bismuth alloy with low melting (around 70 °C) and low setting temperatures and is primarily used for making forensic toolmark casts. It is also called fusible alloy or Leibowitz’s alloy.

The composition of Woods’s metal by weight bismuth (50%), lead (25%), tin (12.5%), and cadmium (12.5%). However, because of toxic lead and cadmium, a new modified wood’s metal (called Field’s metal) replaces these two metals with indium.

As they are available in solid metal, their application needed to be heated to make a viscous solution. And because of very dense viscous liquid and absorbing energy (not like a dental stone that is exothermic) tends to make crips and high detailed reproduction.

Uses: Metal alloy casting materials are not commonly used for shoe or tire marks over the surface but for preparation of tool mark cast. They are very popular and recommended for took marks cast preparation.

Preparation of Wood’s Metal Casting Material

- In a high-quality ceramic pot with wood’s metal, it is heated.

- While heating, avoid inhalation of fumes and stirring.

- Once fully melted, let it be cooled for 1-2 minutes (make it denser).

- Pour the mix from a side on the tool mark impression that naturally covers the surface.

- Setting time is usually up to 10 minutes.

Advantages:

- Crisp and accurate detailing on snow.

- On of the highest dimensional stability and resist degradation.

- Fast setting and curing time.

Disadvantages

- Toxic fumes.

- Only recommend to use for tool marks impression casting.

- Set very fast at low temperature.

- Comparable costlier.

[Table] Comparison Among Different Types of Forensic Casting Materials

| Forensic Casting Materials | Dimension Stability | Ease of Application | Detail Capturing | Hardening Time (mins) | Low Temp Application | Cost-effective |

|---|---|---|---|---|---|---|

| 1. Plaster of Paris | 9 | 7 | 8 | 45 | 3 | 9 |

| 2. Dental Stone | 9.5 | 9 | 9 | 30 | 3.5 | 8 |

| 3. Siloxanes (Sta Seal) | 9 | 8 | 9.5 | 20 | 3 | 5 |

| 4. Siloxanes (Microsil) | 8 | 7 | 10 | 20 | 2 | 5 |

| 5. Polyvinyl Siloxane | 8.5 | 7 | 10 | 10 | 2 | 4 |

| 6. Polyether Gums | 6 | 7 | 7 | 15 | 3 | 4 |

| 7. Polysulfide Gums | 3 | 5 | 9 | 45 | 3 | 6 |

| 8. Polyurethane | 8 | 5 | 10 | 15 | 3 | 4 |

| 9. Sulfur Cement | 9 | 4 | 10 | 30 | 9 | 5 |

| 10. Woods Metal | 9 | 5 | 10 | 10 | 6 | 5 |

8 Best Forensic Casting Materials For Shoes and Tool Marks

In the market, there are tons of casting materials whose choice for use depends both on surface and casting types. Following are some of the casting materials that are commonly used in casting on crime scenes or in laboratories.

1. Isomark Footprints

Mess-free. Fast. Play-and-go casting. This is true for Isomark casting products. Isomarks offers a variety of products, including the most commonly used Isomark footprints.

It is a two-part silicone paste that comes in cartridges with an applicator. This mechanical delivery system simplifies two processes: the first is mixing the base with the hardener, and the second is delivering the mixed batter directly over the shoe impression. Following is the image of ready-to-buy cartridges fillups by Isomarks.

With a nozzle delivery system, Isomark has more advantages such as an easy application on vertical and overhead marks. Plus, it provides a fast setting time (3 to 10 minutes) and works even on snow. All of this makes it ideal for casting at crime scenes.

However, if you have to cast a bigger area such as tire marks or multiple shoe marks on a daily basis, then it can cost you more.

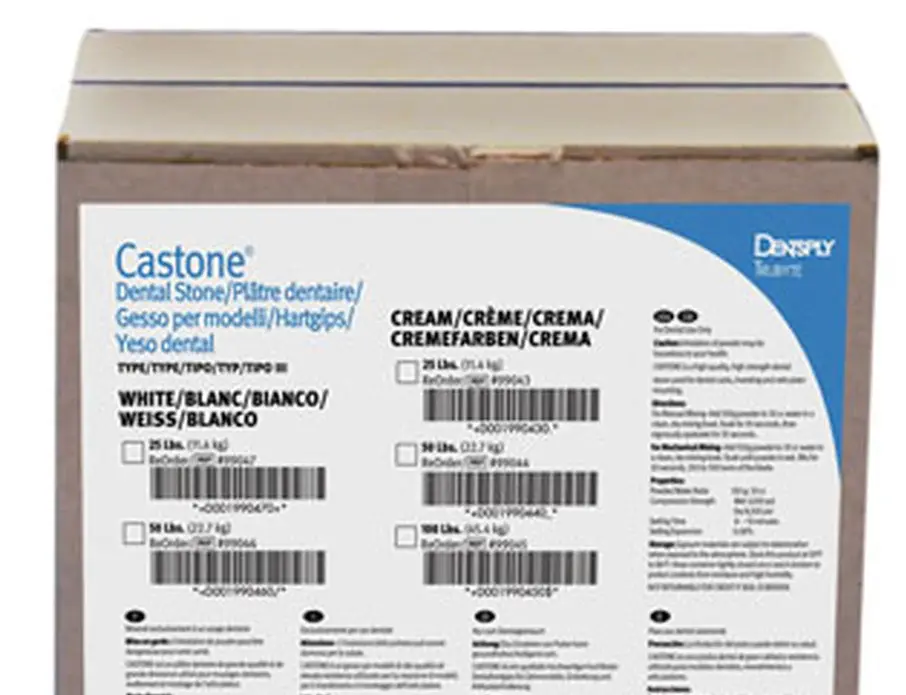

2. Dental Stones by Castone

Castone Dental stone is sold in bulk and pre-weight containers. They are one of the most high-quality dental stones with a setting time of around 15 minutes. However, for colder environments, the setting time can stretch to 40 to 45 minutes.

Castone casting material comes with standard high compression strength at 8,000psi. And for preparing castone paste, 2 pounds/10 ounces water, is recommended for regular sneakers marks.

3. Cast-Pro Dental Stone

Cast-Pro dental stone commercially available in bulk (50lb) and pre-weight shakable bags of weight 2lb, 3lb, and 4lb. The most recommended powder-to-water ratio is 2 pounds/12 ounces of water.

For preparation, add 2 pounds of Cast-pro dental powder in a Ziploc bag. Add 12 ounces of water to it. Squeeze the mixture with both hands till it makes a fine paste. Squeezing should be continued for at least 5-10 minutes, depending on the paste you’re preparing.

The normal setting time of Cast-pro Dental stone is 15 to 20 minutes. But if the temperature is low, it should be allowed to sets for 40 to 45 minutes. It has one of the highest expansion rates of 12%.

Inquiry About the Cast-Pro Stone

4. NuCast 180

Castone and Cast-Pro casting materials have a major drawback i.e. they require a longer setting time, which can range from 20 to 45 minutes depending on the climatic conditions. NuCast 180 eliminates this disadvantage.

It takes 3 to 5 minutes to set. And provides 35 seconds of astonishingly quick paste preparation. This makes it the fastest material for casting shoe and tire marks without sacrificing detail.

NuCast materials are only available in disposable and recyclable pre-weight containers weighing 1.1 lbs (NuCast 180 for shoe prints) and 2.2 lbs (NuCast 180XL for tire marks).

It has a slightly higher compression strength (approximately 8557 psi) than the other two (Castone and Cast-Pro) with a much lower expansion rate (lower is better) of 0.06 % in 48 hours.

5. Traxtone Casting Material

The setting time of Traxtone is about 25 minutes (highest among Castone, Cast-Pro, and NuCast). However, it is one of the most widely accepted casting materials in forensics.

The two quality that makes Traxtone so popular are:

- Produce highly detailed impressions of shoe and tire marks (majorly), and

- Higher compression strength of 18000 psi than other casting materials.

These two qualities are addressed by the use of high-quality diestone dental stone material. Commercially, it is available in two color options: std green and buff, and the Traxtone kit include:

- Five pre-weight bags weighing 2lb each.

- Hair spray to hold loose dirt and sand.

- Measuring container.

- 30.5 cm or 12-inch wooden ruler.

6. Mikrosil Cast

Based on flexible silicone elastomers, it is one of the most popular casting materials for tool marks and firearms marking. Because of elasticity, it favors more application to non-even surfaces and round edges of bullets, cartridges firing pins impressions, and tool marks.

It is too sensitive to detailing and reproduces very accurate detailing, even fingerprints can be lifted using Mikrosil. Used both in fieldwork and laboratory work.

Mikrosil system comes in a two-pack system: a base and hardener. Commercially, the Mikrosil kit comes with a silicone base, hardener, mixing cards, and wooden mixing stick, and four major colors: black, white, gray, and brown.

- Black Mikrosil: lift latent prints developed with white, gray, or fluorescent powders.

- White Mikrosil: lifting developed latent prints using black powder.

- Gray Mikrosil: tool marks, latent fingerprints, postmortem detailings.

- Brown Mikrosil: tool marks impression.

Drawback: Not cost-effective for shoe and tire marks.

7. Permlastic Casting Material

It is a type of polysulfide elastomer with a higher detail capturing ability. They are not commonly used to make the primary cast but to recast from silicone rubbers. This type of recasting helps in building replicas that can be vital for matching metal tools’ impression with the possibility of being physically fit match. And has higher tearing strength.

Commercially, available in a single-mix with three options based on viscosity:

- Regular Permlastic: partial and full denture marks and offers the finest details.

- Light-Bodied Permlastic: inlay and fixed bridge impression

- Heavy-Bodied Permlastic: highest viscosity and compression strength and used on stiffer non-flexible materials.

Drawbacks: It degrades in a relatively short time that making it not suitable for long-term storage. Secondly, if you’re using Permlastic to recast specifically over Isomark impression, it doesn’t cure properly (but works fine with other silicone elastomers). Third, it can cost you way higher for shoes and tool marks.

8. Silmark Casting Material

Silmark is a silicone-based elastomer and you even called it a cheap alternative to Mikrosil. It usually comes in a gray color paste with high pigmented concentration that allows comparable less light reflection and transmission. This enables an optimum sharpness in microscopic analysis and excellent contrast while photographing.

The commercial packs come in a cartridge system just like Isomark and offer an easy mixing and mess-free application on vertical surfaces. So, at the nozzle, the dispenser mixes and releases an equal amount of Silmark base and hardener on squeezing the applicator trigger (like a glue gun).

It comes in two viscosities:

- Low viscosities: test impression at the lab, and tendency to flow helps in capturing more details.

- Medium Viscosities: for casting at the crime scene

General FAQ

Which is the most recommended product for casting impressions over vertical and overhead surfaces?

Isomark and Silmarks are two casting materials that come with a syringe for application. These applicators do not require any paste preparation or mixing and only disperse paste when squeezed. This allows easy casting on overhead and vertical surfaces while maintaining surface detailing.

What are the most common materials used to make casts in forensic science?

Dental stone, Siloxanes, Polyvinyl Siloxane, polysulfide gums, sulfur cement, Woods metal are commonly used at crime scenes and laboratories to cast shoe prints, tire marks, tool mark impressions, firing pin marks, and other casting impressions.

Which is the best method to make casts in a Container or Ziploc bag?

Ziploc is a simple, mess-free method of preparing cast material. A forensic expert only needs to squeeze the transparent Ziploc bag with both hands until the mixture thickens into a fine paste. It also prevents air bubbles formation, which is very common in elastomer-based casting.

References:

- https://www.sciencedirect.com/science/article/pii/B9780123741349500167

- https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4714405/

- https://www.sciencedirect.com/science/article/abs/pii/0379073896019640

- https://www.sciencedirect.com/science/article/abs/pii/S0894113002500296

- https://www.evidencemagazine.com/index.php?option=com_content&task=view&id=504

- https://www.ojp.gov/ncjrs/virtual-library/abstracts/sulfur-cement-new-material-casting-snow-impression-evidence

- https://forensicresources.org/wp-content/uploads/2019/07/Dental-Stone-02-01-2019.pdf

Read More:

- 7 Importance of Casting In Forensic Crime Investigation [Explained]

- How to Cast Shoe Impression on Snow? Forensic Casting Materials

- Photogprahing Shoe and Tire Impression on Snow With Highlighting Materials

- Mortar and Concrete Analysis: Forensic Aspects & Chemical Tests

- Adulteration of Cement: Test, Chemical & Instrumental Analysis

FR Author Group at ForensicReader is a team of Forensic experts and scholars having B.Sc, M.Sc, or Doctorate( Ph.D.) degrees in Forensic Science. We published on topics on fingerprints, questioned documents, forensic medicine, toxicology, physical evidence, and related case studies. Know More.