| Fingerprint Powders | Features | Surface to Used |

|---|---|---|

| Granular Powders | Carbon-based asymmetrical spherical particles | All types of surfaces |

| Metal Flake Powders | Have flakes particles | All types of surfaces |

| Magnetic Round Powders | Alternative to regular fingerprint powder | Non-porous, Non-magnetic, and horizontal surfaces |

| Magnetic Flake Powders | More efficient than magnetic spherical powders | Non-porous, Non-magnetic, and horizontal surfaces |

| Luminescent Powders | luminescent under special radiation | Multi-colored surfaces |

| Thermoplastic Powders | Develop a permanent fingerprint on the surface | All types of surfaces |

| Nano Powders Powders | Highest sensitivity than any other powder | Prints can’t be developed using regular methods |

| Anti-Stokes Powders | Developing prints become clearly visible in IR radiation | Surface with strong luminescence |

| Bichromatic Powders | Only powder doesn’t need to care color of surface | Both light and dark-colored surfaces |

1. Granular Powders

Granular powders come in different colors like black, white, red and have a specific granular texture, that gives its name.

The common black granular powder is made of carbon-based asymmetrical particles which are used to develop fingerprints on non-porous surfaces like finished wood, windows, and mirrors.

It can be applied using a brush made of polyester or animal hair but the most preferred combination is a fiberglass brush that is made of bundles of soft glass fibers. (Read More: Disadvantages of fiberglass brushes.)

These fibers are 12 μm diameter bristles that evenly distribute the powder over the latent print. These developed prints can then be lifted using fingerprint tape on a contrasting fingerprint card.

2. Metal Flake Powder

Metals like aluminum, zinc, iron, or copper are used for this purpose. The flattened flakes of metal are deposited in thin layers over the latent print and result in high-contrast prints with minimum background noise.

The most common metal preferred for this is aluminum which is used on dry and smooth surfaces.

When aluminum does not produce sufficient contrast with the substrate, another metal like copper is used. It is commonly used in European crime investigations.

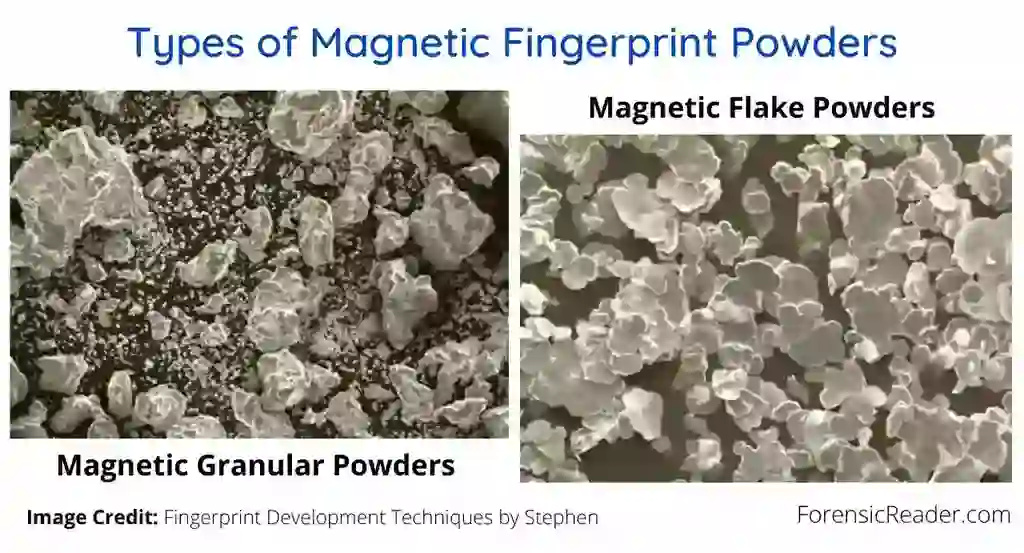

3. Magnetic Powders

Magnetic powder consists of fine carbon particles that are blended with ferrous to give it a magnetic property.

It is available in different colors including fluorescent formulations for different substrate backgrounds.

These powders are applied using an applicator with a magnetic tip and it looks like a pen. The applicator is dipped into the powder which forms a “brush” which is referred to as a magnetic brush or magnetic wand.

The prints developed by this method are then lifted using lifters, tape, or silicone rubber material.

It is suitable for greasy surfaces and has less background noise owing to its fineness. Also, the magnetic brush does not disturb the print details and is more sensitive.

4. Magnetic Flake

Magnetic flake powders are a superior version of magnetic powders. The development of magnetic flake powder has resulted in enhancing the benefits of the Magna-brush fingerprint technology.

Iron flakes are used to form the Magna brush. It prevents the delicate ridge details from damaging under a conventional brushing technique like fiberglass.

With the reduction of ridge smearing, the clarity and sensitivity of the print-developing technique are also amplified.

5. Luminescent Powders

These use a type of nanoparticle that remains luminescent even after the source of radiation ceases to excite it.

The earth metal oxides were functionalized with carboxyl groups to react with the amino group in the sweat residues of the latent print. This gave rise to time-gated imaging of the fingerprint.

Moreover, old samples gave more clarity due to highly stable amino groups. Combined with concanavalin A, the nanoparticles also react with glycoproteins to give fluorescence.

It is a versatile and effective method of fingerprint development that minimizes background noise, especially when dealing with multicolored documents.

6. Thermoplastic Powders

This includes using toners from photocopiers and dry inks to develop latent fingerprints.

The powder is dusted over the latent print and it adheres to the sweat residues forming the ridge patterns. This layer of deposition fuses into the surface when exposed to heat and the excess powder can be dusted off.

The toner powder can also be fixed by spraying vapors of ethyl ether from a distance of 10cm.

The surface is then immediately covered with a glass hood to avoid inhalation of the fumes and speed up the fixing process.

The pattern can then be visualized and rest on the surface for months without alterations. There is no need for the print to be lifted and this is a versatile technique that can be used on any type of substrate.

Read More: 11 Reasons Why Fingerprints Used for Identification: A Forensic Aspect

7. Nano Powders

Nanopowders are fine particles with a diameter of less than a micron. It can be fluorescent or infrared and can be mixed with magnetic powder for more effectiveness.

It can be applied dry or mixed with an aqueous medium. The medium solution is more selective and hence more sensitive to latent prints.

Nanoparticles as a latent fingerprint development technique is an emerging technology with more complexity like photoluminescent semiconductor nanocomposites.

It is also suggested to be a biohazard due to its nano size.

8. Anti-Stokes Powders

For surfaces that show strong luminescence, most of the fingerprint development is not effective. That is why the application of anti-Stokes powders was used. Surfaces such as reflecting metal cans are best for anti-stokes powders.

This requires a source of illumination that radiates light in the infrared range (this is why sometimes it is called infrared fingerprint powder).

The anti-Stokes powders upconvert the long wavelength radiation of the infrared source to the short wavelength radiation of visible light range.

The particles are composed of rare earth elements activated compounds like yttrium oxides and other compounds like oxychlorides and oxysulphides.

9. Bichromatic Powder

It is used for both light and dark-colored surfaces to increase the effectiveness of visualization.

It is formed by combining the black powder with a highly reflective powder like aluminum powder. This results in a dark print on light surfaces and reflective prints on dark surfaces.

However, this mixing of different particles might affect the adhering capacity of the powder and give an insufficiently developed print. Fluorescent dyes are used in such cases.

The developed prints can then be photographed or lifted using tapes. Bichromatic powders are also known to be biohazardous that irritate eyes and skin and need proper protection before use.

References:

- Bogdan, D., et al. Applying Anti-Stokes Phosphors in Development of Fingerprints on Surfaces Characterized by Strong Luminescence. Journal of Forensic Identification. [OJP.Gov]

- Hillary Moses Daluz. Fundamentals of Fingerprint Analysis. Boca Raton, Crc Press, 2021.[Google Books]

- James, Jonathan D., et al. Magnetic Flake Powders for Fingerprint Development. Journal of Forensic Sciences, vol. 38 [ResearchGate]

- Lee, Henry C, and R E Gaensslen. Advances in Fingerprint Technology. Boca Raton, Fla., Crc Press, 2001.

- Wang, Jie, et al. Time-Gated Imaging of Latent Fingerprints and Specific Visualization of Protein Secretions via Molecular Recognition. Analytical Chemistry, vol. 89 [Pubs]

FR Author Group at ForensicReader is a team of Forensic experts and scholars having B.Sc, M.Sc, or Doctorate( Ph.D.) degrees in Forensic Science. We published on topics on fingerprints, questioned documents, forensic medicine, toxicology, physical evidence, and related case studies. Know More.