Fibers are a valuable type of evidence in solving cases. They can be used to identify suspects, victims, and location of crimes.

The steps involved in processing fiber evidence include recovery, identification, comparison, and evaluation.

In all, one of the essential aspects of forensic analysis is the examination of fibers found at crime scenes.

Chemical analysis of fibers can provide valuable insights into a case, helping investigators link suspects to the scene or victims[1].

Moreover, like other evidence, proper documentation and analysis are essential to ensure the reliability of fiber evidence in court.

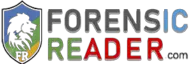

Classification of Fibers

Fibers can be classified in a number of ways, including by their origin, chemical composition, and physical properties[2].

Classification 1: By Origin

Fibers can be classified as natural and synthetic based on their origin.

- Natural Fibers: These are derived from plants or animals. Some of the most common natural fibers include cotton (plant), wool (animal), silk (insect), linen (plant), and natural minerals (Asbestos).

- Synthetic Fibers: These are man-made fibers produced from petrochemicals. Examples include polyester (a polymer of ester), nylon, acrylic, spandex, etc.

Read More: Paper Fiber and Pulp Analysis: How They Impact Questioned Documents Examination?

Classification 2: By Chemical Composition

Fibers can also be classified as cellulosic and protein fibers based on their chemical composition.

- Cellulosic Fibers: These are made up of cellulose, a polysaccharide found in plant cell walls. Common examples of cellulosic fibers include cotton, linen, and hemp.

- Protein Fibers: These contain biopolymers made up of amino acids. Examples are wool and silk.

Classification 3: By Physical Properties

- Fibers can further be classified by their physical properties, such as their strength, elasticity, and durability.

- For instance, some fibers are strong and durable, while others are soft and elastic.

Other Classification Systems

Apart from the above systems, fibers can also be classified based on:

- Their end use, such as textile and industrial fibers,

- Manufacturing processes, like staple fibers and continuous filament fibers, etc.

Forensic Examinations of Fibers: Destructive and Non-Destructive Approach

Forensic fiber tests are used to identify the type of fiber and to distinguish between natural and synthetic fibers. They also help in determining the chemical composition of fibers and identifying any dyes or treatments that have been applied to the fibers[4].

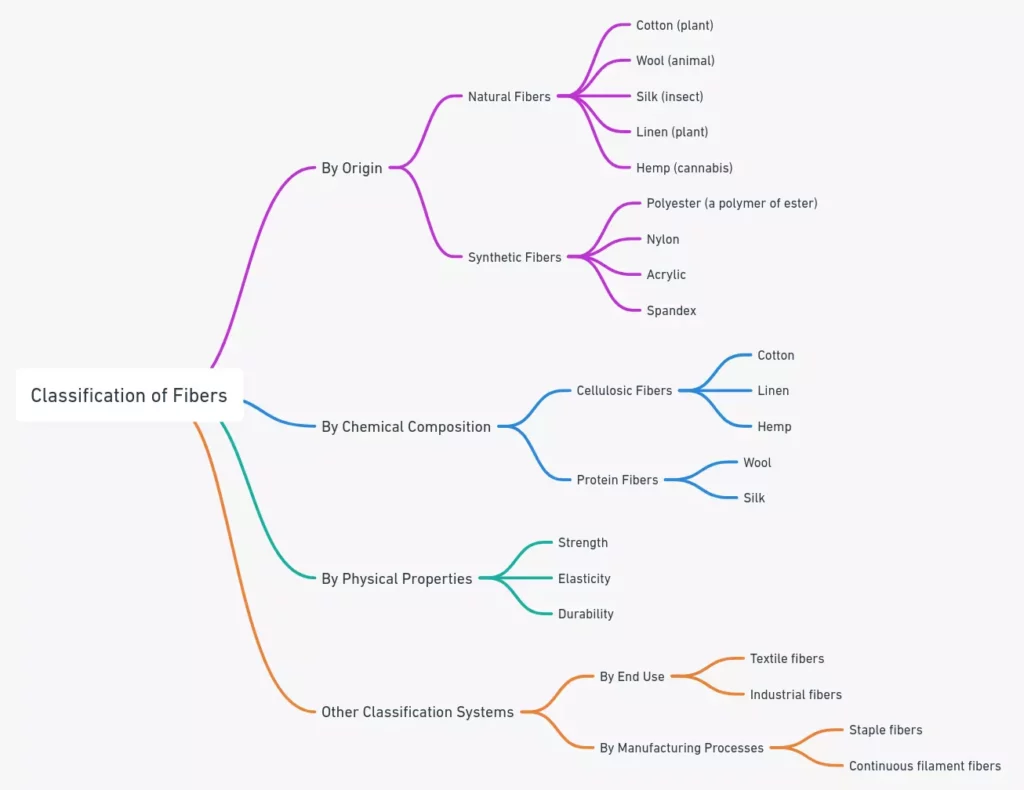

Before jumping to forensic chemical analysis of fibers, there are two categories into which tests can be divided:

- Non-Technical Tests: Burning and Feeling/Texture tests.

- Technical Tests: Melting point tests, Microscopic tests, and Solubility tests.

Note: All chemical tests are destructive in nature. So make sure you first perform microscopic analysis and only proceed with chemical tests when necessary.

1. Texture/Feeling Test

The texture test is a more subjective method used to identify fibers based on their texture and feel.

- Natural Fibers: E.g., Cotton is typically soft and smooth, while wool is coarse and wiry.

- Synthetic Fibers: These can have a variety of textures but are often stiffer and less breathable than natural fibers[6].

| Fiber Type | Texture |

|---|---|

| Cotton | Soft and smooth |

| Wool | Coarse and wiry |

| Nylon | Stiff and slippery |

| Polyester | Stiff and crisp |

| Acrylic | Soft and fluffy |

| Acetate | Silky and smooth |

| Rayon | Soft and drapey |

2. Microscopic Characteristics of Fibers and Their Analysis

Microscopic examination of fibers is a technique used to identify the type of fiber and to distinguish between natural and synthetic fibers. It is also employed to determine the physical characteristics of fibers, such as their size, shape, color, and cross-sectional structure.

- Microscopic Examination Tools: Microscopic examination of fibers can be conducted using a variety of microscopes, including optical microscopes (compound and simple), and electron microscopes (SEM and TEM).

- Optical Microscopes: These are the most commonly used type for fiber analysis due to their accessibility and ease of use.

- Electron Microscopes (SEM and TEM): These can be used to obtain more detailed images of fibers, but they are more expensive and require more specialized training to operate.

| Fiber Type | Microscopic Characteristics |

|---|---|

| Cotton | Spiral twist, lumen |

| Wool | Scaly appearance, medulla |

| Silk | Smooth surface, triangular cross-section |

| Linen | Long and narrow, smooth surface |

| Polyester | Smooth surface, round or elliptical cross-section |

| Nylon | Smooth surface, serrated cross-section |

| Acrylic | Smooth surface, bean-shaped cross-section |

| Spandex | Smooth surface, round or oval cross-section |

3. Melting Point Test

The melting point test can distinguish between natural and synthetic fibers by determining the temperature at which a fiber melts.

Natural Fibers:

- They generally do not melt; instead, they tend to char or decompose when exposed to high temperatures.

- Example: Cotton, being a natural fiber, will not melt but will burn and eventually turn to ash at high temperatures.

Synthetic Fibers:

- They typically have a specific melting point at which they melt and may even shrink from a flame.

- Example: When polyester is subjected to heat, it will melt at a specific temperature (typically around 260-290 °C).

| Fiber Type | Melting Point |

|---|---|

| Cotton | 130-150 °C |

| Wool | 200-250 °C |

| Nylon | 250-300 °C |

| Polyester | 260-290 °C |

| Acrylic | 250-280 °C |

| Acetate | 250-280 °C |

| Rayon | 200-250 °C |

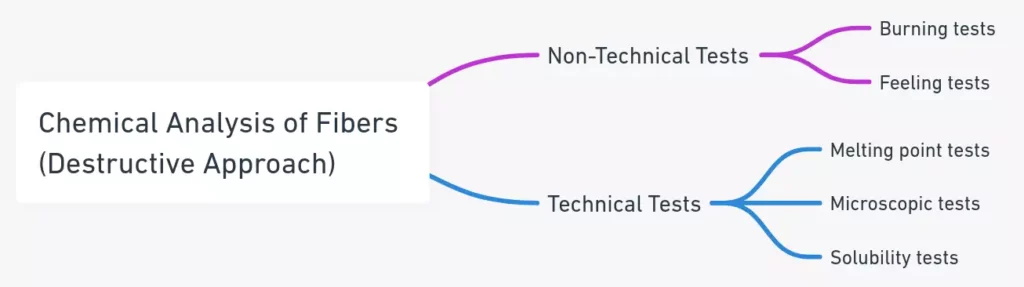

4. Burn and Flame Test

The burn test is a rudimentary test and is based on how fibers (as evidence) react to flame and the type of smoke they produce when burned.

Natural Fibers:

- When subjected to flame, natural fibers usually burn and may continue to glow after the flame is removed, producing a characteristic odor.

- Example: Wool will burn and may produce a characteristic burnt hair odor (because of keratin), leaving behind a black, crushable ash.

Synthetic Fibers:

- Tends to melt and shrink away from the flame, and they often extinguish once the flame is removed, producing a different kind of smoke and odor compared to natural fibers.

- Example: Nylon will melt and shrink away from the flame, often extinguishing once the flame is removed, and may produce a celery-like odor and black smoke, leaving behind a hard, bead-like residue.

This test is not definitive but is useful for narrowing down the possible types of fibers.

| Fiber Type | Burn Test |

|---|---|

| Cotton | Burns with a flame and produces a white ash. |

| Wool | Burns with a flame and produces a black ash with a characteristic burnt hair odor. |

| Nylon | Melts and produces black smoke. |

| Polyester | Melts and produces black smoke. |

| Acrylic | Melts and produces white smoke with a characteristic plastic odor. |

| Acetate | Melts and produces black smoke with a characteristic vinegar odor. |

| Rayon | Burns with a flame and produces a white ash but will extinguish itself when the flame is removed. |

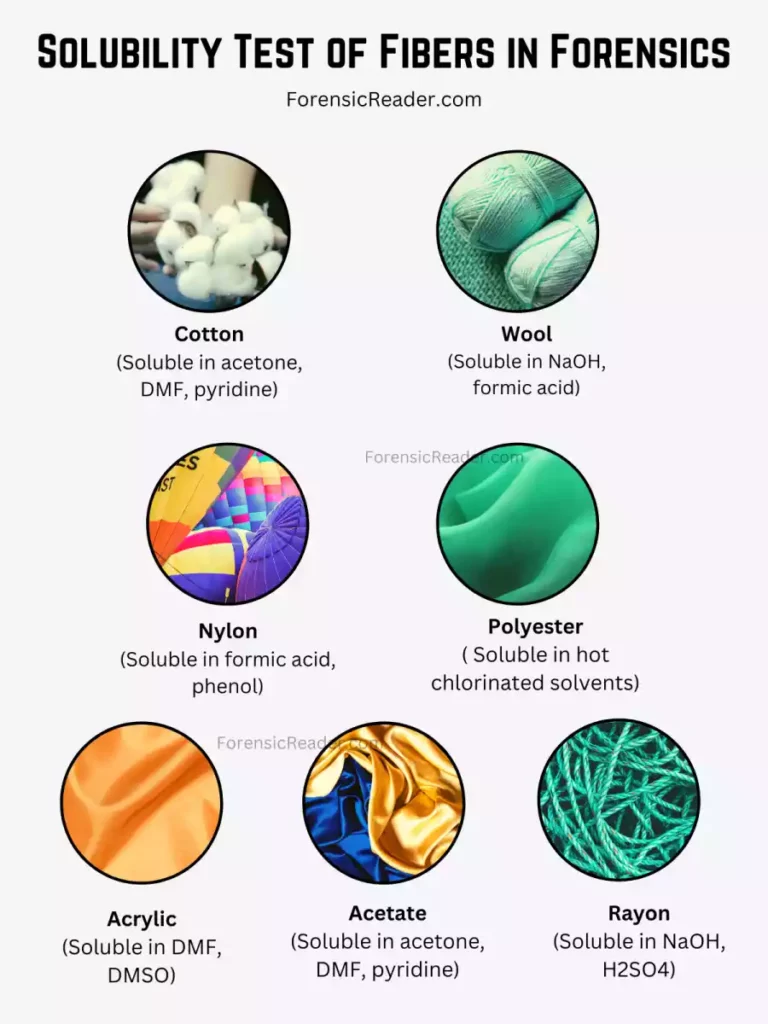

5. Solubility Test

The solubility test is another rudimentary test used to distinguish between natural and synthetic fibers.

Procedure: A small sample of the fiber is placed in a solvent, such as acetone or sodium hydroxide.

- Natural Fibers: Typically soluble in certain solvents.

- Synthetic Fibers: Typically not soluble.

This test can be more definitive than the burn test. Still, it is important to use other tests to confirm the identity of a fiber due to some natural and synthetic fibers having similar solubility properties.

Note: All of the fibers listed in the table are insoluble in water.

| Fiber Type | Solubility in Common Solvents |

|---|---|

| Cotton | Soluble in acetone, dimethylformamide, and pyridine |

| Wool | Soluble in sodium hydroxide and formic acid |

| Nylon | Soluble in formic acid and phenol |

| Polyester | Soluble in hot chlorinated solvents, such as dichloromethane and trichloroethylene |

| Acrylic | Soluble in dimethylformamide and dimethyl sulfoxide |

| Acetate | Soluble in acetone, dimethylformamide, and pyridine |

| Rayon | Soluble in sodium hydroxide and sulfuric acid |

6. Dye Test for Fibers

The dye test can be used to identify the type of dye applied to a fiber. It helps in determining the possible source of origin of a fiber, albeit not conclusively.

Procedure:

- Take a small sample of the fiber.

- Place the fiber sample in a water solution or ethanol.

- Heat the solution with the fiber sample in it.

- After heating, examine the fiber under a microscope and the amount of dye absorbed cross-sectional.

- Observe any color changes in the fiber.

- Document any color changes and the type of dye absorbed by the fiber for further analysis.

Observation: If the fiber absorbs any of the dyes, the color of the fiber will change[5] and the amount of soaking ability is much higher in natural fibers than in synthetic.

This information can help in narrowing down the possible sources of the fiber. Read the following examples:

Example 1: Fiber A (Cotton):

- If a cotton fiber is placed in the dye solution, it absorbs a specific dye, changing its color.

- This indicates that the fiber is natural and cellulose-based, as cotton is known to absorb dyes well due to its cellulose composition.

Example 2: Fiber B (Polyester):

- If a polyester fiber is placed in the same dye solution, it does not absorb the dye or change color differently compared to cotton.

- This can indicate that the fiber is synthetic and likely made from polymers, as polyester fibers usually have non-absorbing properties due to their synthetic nature.

Read More: Identification of Paper Additives: Fillers, Oil, Waxes, and Pigment

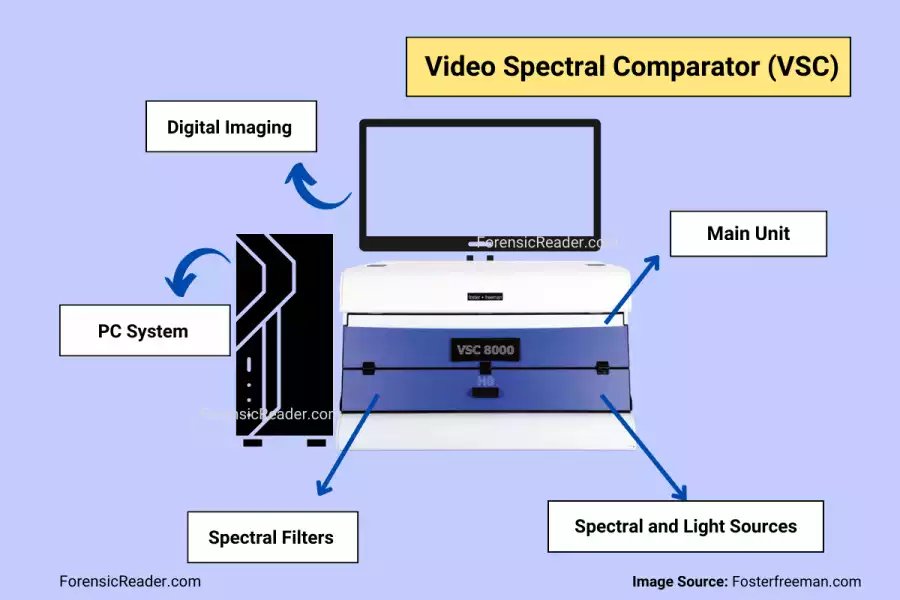

Spectroscopy Examination of Fibers: A Non-Destructive Approach

Spectroscopy, specifically techniques like ATR-FTIR and FT-Raman, is pivotal for analyzing fibers. It involves studying the interactions between matter and electromagnetic radiation.

This helps the forensic examiner to extract detailed information about the molecular composition, chemical structure, and physical properties of fibers.

1. Dye and Pigment Analysis Using UV-Visible Spectroscopy

- Application: For analyzing dyes and pigments in fibers.

- Example: The absorption spectra obtained can be compared to known standards to identify specific dyes and pigments.

2. Identification of Chemical Composition Using IR

- Specific Techniques: ATR-FTIR and FT-Raman are pivotal for analyzing fibers.

- Application: Allows for the differentiation between various synthetic and natural fibers through the detection of specific functional groups like carbonyl or amine groups.

- Example: Using ATR-FTIR, analysts can identify the unique infrared absorption spectra of fibers. A fiber sample with a characteristic peak at 1720 cm⁻¹ could indicate the presence of a carbonyl group, typical in polyester fibers, allowing for more precise identification[7].

3. Structural Analysis using Raman Spectroscopy

- Application: Provides insights into the molecular vibrations within the fiber, enabling the identification of molecular structures and polymorphs.

- Example: Differentiation between various crystalline structures in synthetic fibers like polyethylene.

4. Microspectrofluorimetry

- Application: Allows for the detailed analysis of the color and optical properties of fibers (especially useful when examining dyed fibers).

- Example: Microspectrofluorimetry is essential for analyzing the fluorescence of fibers. For instance, a fiber treated with a specific flame retardant might exhibit a distinctive fluorescence signature under UV light.

- If a cotton fiber exhibits fluorescence at 460 nm, it might indicate the presence of a specific optical brightener or flame retardant, providing another layer of specificity to the analysis[9].

Read More: Forensic Watermark Examination of Paper: Destructive And Non-Destructive Analysis

5. Trace Evidence Analysis using Mass Spectrometry (MS):

- Application: Provides detailed information about the molecular weight and sequence of polymer units in fibers and their dye compositions.

- Example: Identification of trace components or additives in fiber samples.

6. Comparative Analysis with Database Integration

- Application: Allows forensic analysts to compare the spectroscopic profiles of unknown fibers with known samples.

- Example: A forensic analyst might compare a fiber found at a crime scene with fibers cataloged in the National Fiber Databank.

- If a match is found, say a unique dye in an acrylic fiber that corresponds to a specific manufacturer, it can significantly narrow down the source and potentially link a suspect or victim to the crime scene[8].

Challenges While Analysing Fibers as Evidence

- Contamination and Sample Degradation: These are persistent challenges that affect the reliability and accuracy of results.

- Limited Sample Quantity: Often, only minute fiber samples are available for analysis, which can limit the types and number of tests that can be performed.

- Instrument Limitations: The limitations of some analytical instruments can hinder the detection of certain fiber characteristics or components, potentially impacting the overall analysis.

- Complexity of Fiber Mixtures: Analyzing mixed fiber samples can be challenging due to the presence of multiple fiber types, dyes, and treatments, requiring careful separation and analysis.

Advancements in Fiber Analysis

- HEPA Filtered Environments: High-Efficiency Particulate Air (HEPA) filtered environments in laboratories have significantly reduced the risk of airborne contamination during fiber analysis.

- Enhanced Microspectrophotometry: Advancements allow for more detailed analysis of fiber coloration and chemical composition, even with minute, degraded samples[10].

- Improved Instrumentation: The continual refinement and enhancement of analytical instruments, such as more sensitive spectrometers and higher-resolution microscopes, have expanded the capabilities of forensic fiber analysis.

Cases Solved Using Fibers As Evidence

Case 1: Darlie Routier [Forensic Files] Invisible Intruder Case

In the 1996 Routier case, a critical piece of evidence was a bread knife found with a single fiberglass rod and rubber dust.

These fibers matched the fiberglass rods from a cut window screen, indicating the screen had been cut from the inside and contradicting the intruder theory.

This fiber analysis was pivotal in solving the case, leading to Darlie Routier’s conviction for the murder of her sons.

Case 2: Beaten by a Hair [Forensic Files] Case

In the 1992 disappearance case of Laura Houghteling, forensic fiber analysis was proven important. A strand of synthetic hair, resembling a wig, was found in Laura’s brush, linking to Hadden Clark, a suspect.

Microscopic examination and microspectrophotometry analysis of this hair matched it to a wig found in Clark’s possession, confirming the fibers were identical.

Fiber analysis, along with other corroborating evidence like matching thumbprints and Clark’s possession of items belonging to Laura, led to the resolution of the case and Clark revealing the location of Laura’s body.

Case 3: Charlene and Brian Hummert [A Tight Leash] Case

In the 2004 case of Charlene Hummert, forensic analysis of a dog leash helped in identifying the culprit.

The forensic linguist, Dr. Robert Leonard, analyzed various letters and concluded that the stalker’s letter, the killer’s misleading letter, and Brian’s writings were all penned by Brian Hummert, Charlene’s husband.

The linguistic analysis, coupled with matching ligature marks from a dog’s leash found in Brian’s possession and his ownership of clothing matching descriptions from enhanced security footage, led to Brian Hummert’s arrest for the murder of his wife.

Case 4: Nice Threads [Forensic Files] Case

In the 1995 case of Dawn Fehring, meticulous solving the case from fingerprints on clothes. Forensic expert Eric Bird made a significant breakthrough by retrieving details from partial blood fingerprints found on Dawn’s bed sheet (a fabric).

These fingerprints were then matched precisely by fingerprint expert Patrick Warrick to a neighbor, Eric Hayden, who had been acting suspiciously and inconsistently during interrogations.

The fingerprint development on fabric and the use of a mathematical algorithm to remove the background led to the arrest and subsequent conviction of Hayden for first-degree murder, solving the harrowing case.

References:

- Robertson, J., Roux, C., & Wiggins, K. G. (2017). Forensic Examination of Fibres. CRC Press.

- Identification of Textile Fibers. (n.d.). Retrieved September 24, 2023, from Textile Coach

- Identification of Textile Fibers—Google Books. (n.d.). Retrieved September 24, 2023, from Google Books

- Frank, R. S., & Sobol, S. P. (1990). Fibres and Their Examination in Forensic Science. In A. Maehly & R. L. Williams (Eds.), Forensic Science Progress (pp. 41–125). Springer. DOI: 10.1007/978-3-642-75186-8_3

- Goodpaster, J., & Liszewski, E. (2009). Forensic Analysis of Dyed Textile Fibers. Analytical and Bioanalytical Chemistry, 394, 2009–2018. DOI: 10.1007/s00216-009-2885-7

- Textile Standards—Standards Products—Standards & Publications—Products & Services. (n.d.). Retrieved September 24, 2023, from ASTM

- Meleiro, P. P., & García-Ruiz, C. (2016). Spectroscopic techniques for the forensic analysis of textile fibers. Applied Spectroscopy Reviews, 51(4), 278–301. DOI: 10.1080/05704928.2015.1132720

- Forensic Fiber Examiner Training Program | Office of Justice Programs. (n.d.). Retrieved September 24, 2023, from Office of Justice Programs

- Hu, C., Mei, H., Guo, H., & Zhu, J. (2020). Color analysis of textile fibers by microspectrophotometry. Forensic Chemistry, 18, 100221. DOI: 10.1016/j.forc.2020.100221

- Stoney, D. A., & Stoney, P. L. (2015). Critical review of forensic trace evidence analysis and the need for a new approach. Forensic Science International, 251, 159–170. DOI: 10.1016/j.forsciint.2015.03.022

A Forensic Science graduate from Rashtriya Raksha University, and certifications in behavioral science, communication, and foreign languages. Known for her analytical proficiency and extensive field experience, solving real-world cases and presenting at prestigious conferences.

FR Author Group at ForensicReader is a team of Forensic experts and scholars having B.Sc, M.Sc, or Doctorate( Ph.D.) degrees in Forensic Science. We published on topics on fingerprints, questioned documents, forensic medicine, toxicology, physical evidence, and related case studies. Know More.